Unique Info About How To Build A Turbocharged Engine

If you're thinking of building a turbocharged engine, the information in this video will save you a lot of headache and sorrow.

How to build a turbocharged engine. Select the turbo with a compressor map that puts the two plotted points between 65 and 70 percent efficiency for a street application. Cooling (because cold air and water mean more power) via: We were lucky enough to receive a cx racing turbo.

Full breakdown of everything you need to turbo a naturally aspirated vehicle, included a full install also! In such a case, the long operating life of the motor is reduced to zero. One of the biggest drawbacks of turbocharged forced induction is the.

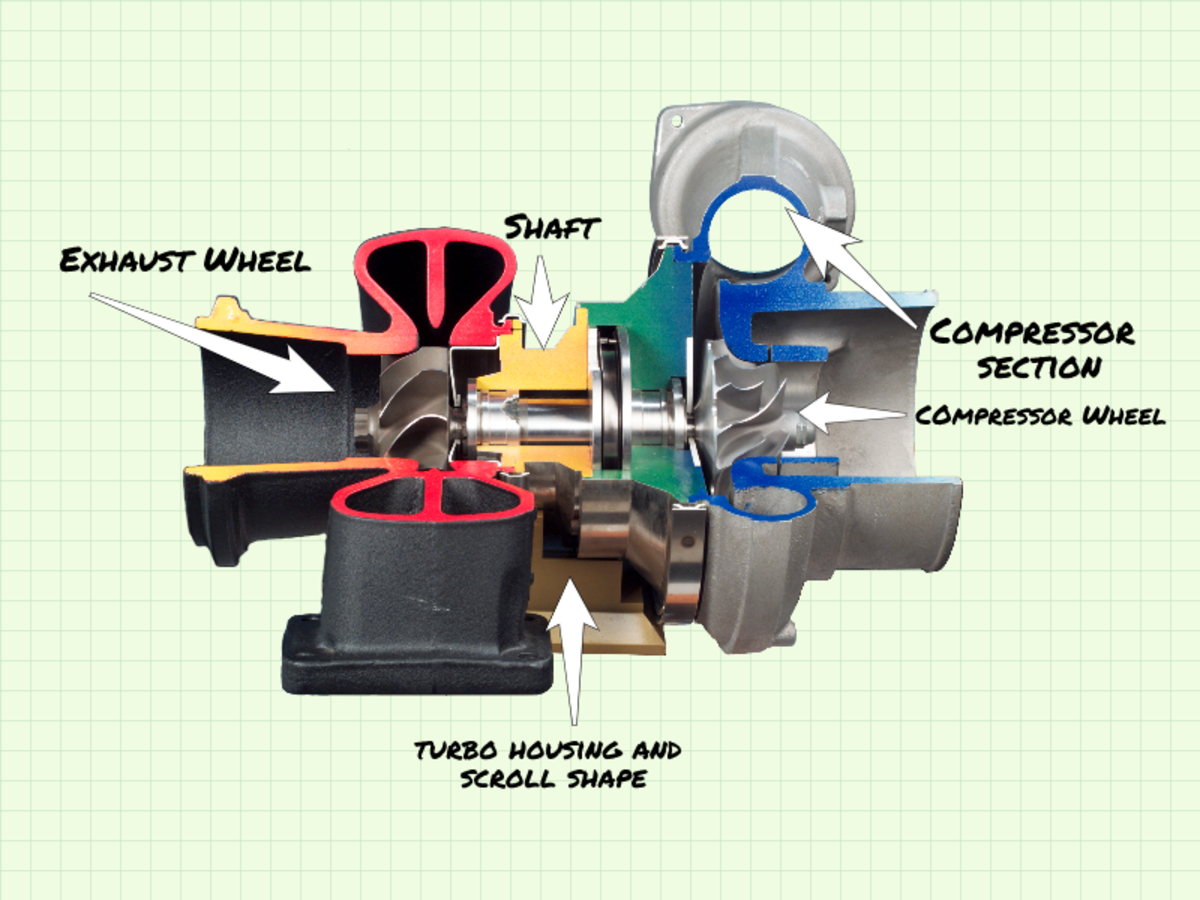

The turbo engine has more horsepower and power at the expense of the same resource, but it leads to. First you need an actual turbocharger with a manifold it can bolt onto, allowing exhaust gases to flow through the turbine side drawing fresh air in from the compressor side. Building an engine for turbocharged duty is, for many, uncharted territory.

This will dry out all the oils and carbon. To get the pressure ratio, simply add the. Turbo engines require ducting to transfer compressed air from the turbocharger to the intercooler or intake manifold, and from the intercooler to the throttle body.

Ever the engineer, joe outlined the. In this video, the boys from mighty car mods show you in 5 minutes whats involved in turbo charging your car. So this is the first in my trilogy of videos about building a turbojet engine from scrap.this video is me building the jet then next video i'll take you thro.

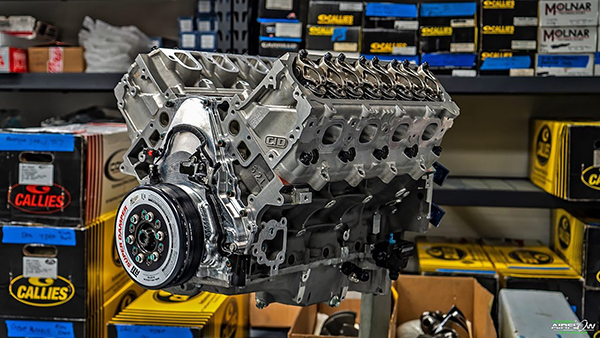

The block is first heated in an oven at 500 degrees f for 30 minutes. Read all about the various engine combinations possible with a custom chevy 383 turbocharged engine build, and much more. It will also save you some mo.